Provide reliable protection for your engine with additional equipment

Our company offers slit filters with laser perforation for various types of wells.

Do you have any questions? Contact us!

I agree to the Terms of Service

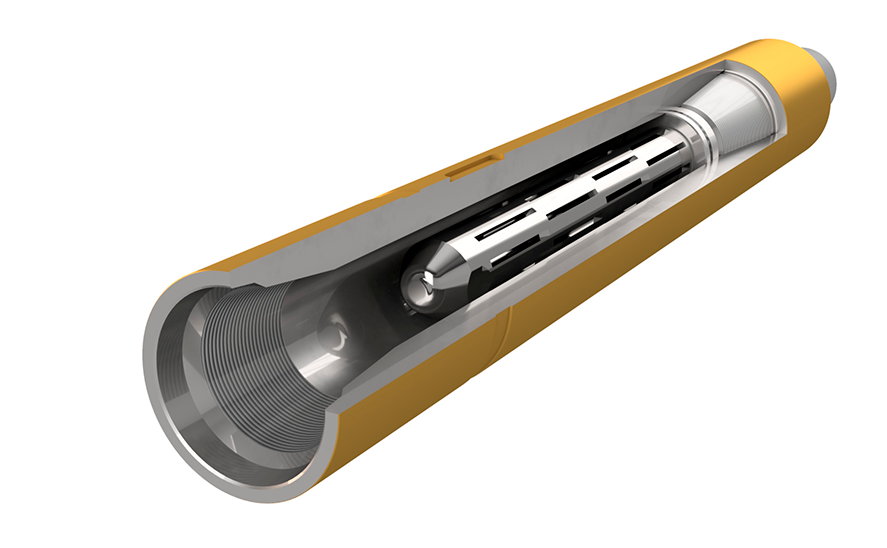

Slot filters

for different types of vsd

The slits have a fairly small width, which makes it possible to effectively control the throughput and detain unwanted particles

01

02

03

our company carries out joint selection, production and supply of filters so that they fully meet your requirements and needs.

Laser cutting ensures high accuracy and quality of slotted wells, which affects the efficiency of the well as a whole

Our slotted borehole filters with laser perforation have a number of advantages:

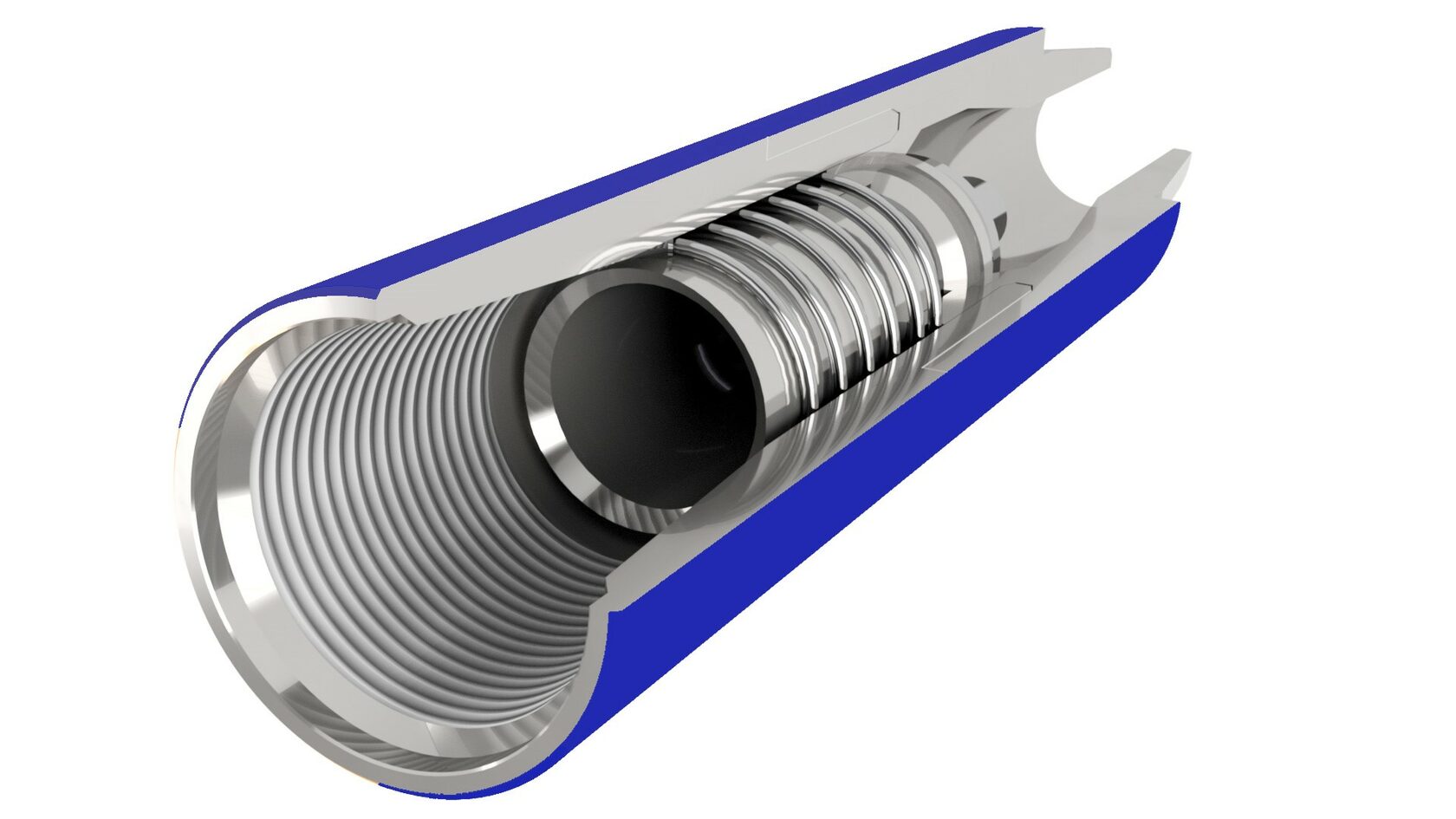

reliable engine protection with check valves

Check valves are designed to prevent sludge and other materials from entering the engine. They allow the fluid passing through the system to move in only one direction - from the drill string to the surface. This ensures reliable protection of the engine from unwanted deposits and increases operational efficiency.

Sludge prevention::

We offer a wide range of high-quality check valves designed to meet the requirements of the industry!

Does your project require reliable and efficient check valves that will protect the engine and prevent sludge?

When equipped with overflow valves, the check valve is installed below the overflow valve. This allows for proper circulation and controlled filling of the drill string, and then safe emptying.

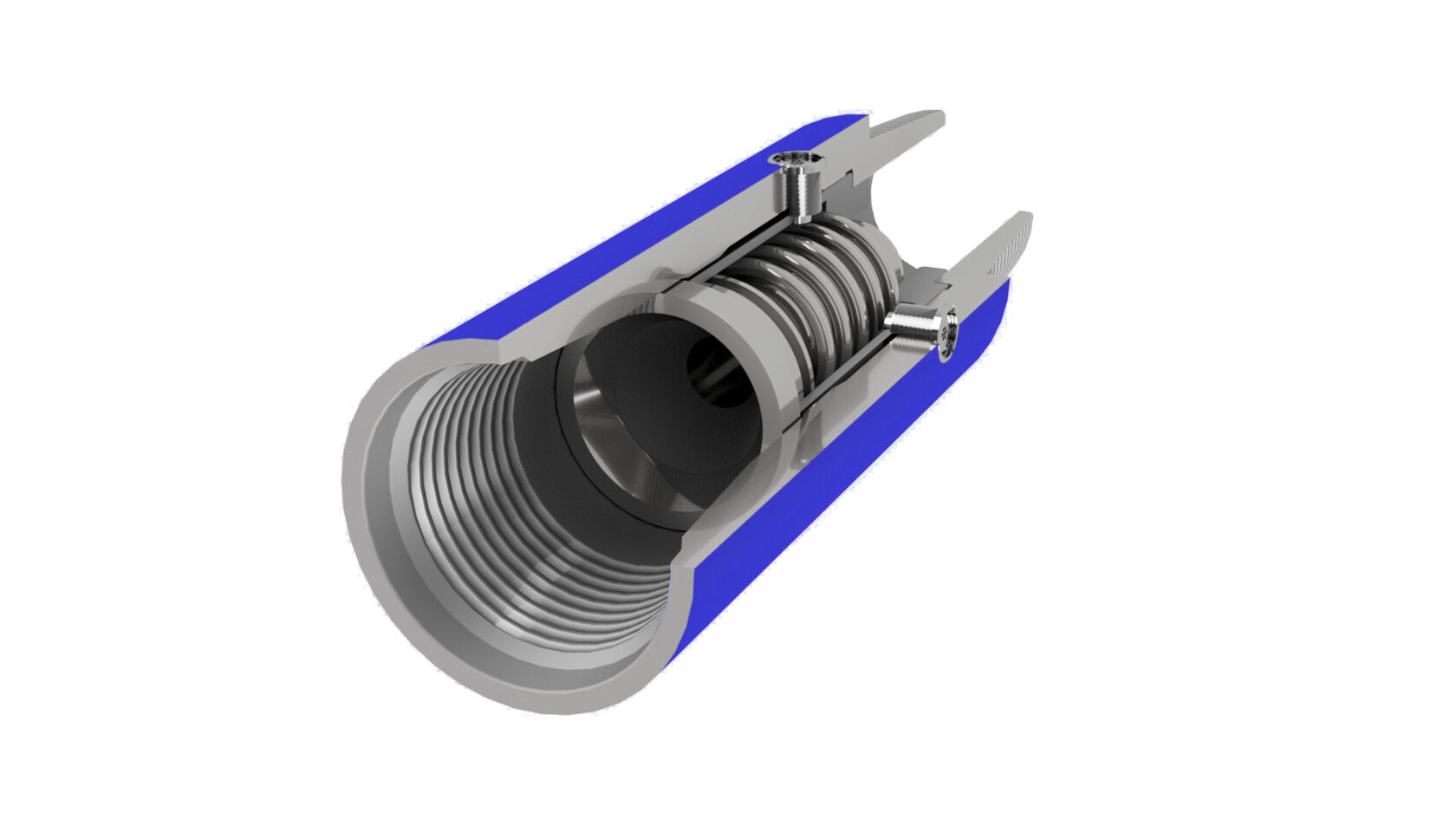

overflow valve:

safety and effectiveness

lifting operations with overflow valves

Safe filling and emptying of the drill string

Overflow valves ensure controlled filling of the drill string with liquid during descent. This is important to create the necessary pressure and stability inside the well, preventing unwanted seepage or loss of drilling fluid circulation.

Filling the drill string:

Overflow valves play a key role in downhill operations during well drilling. They are designed to fill and empty the drill string, ensuring safety and efficiency. Installing the overflow valve above the engine is an integral part of the configuration.

After completing the descent, operators must empty the drill string before lifting. Overflow valves allow you to control the emptying process, ensuring the safe removal of drilling mud and other materials from the well.

Emptying the drill string:

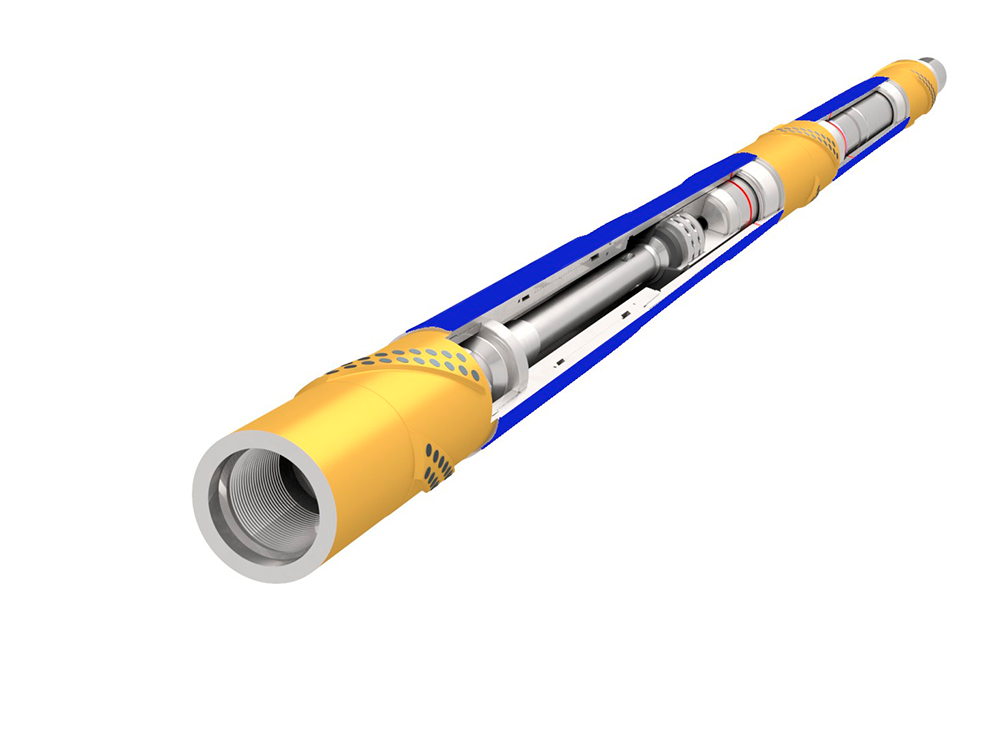

Overhead shock absorbers

to reduce vibrations in the drill string

Our equipment provides effective vibration reduction in the drill string, which improves drilling quality and prolongs tool life. This helps to avoid damage to the equipment and reduces the risk of problematic situations during work.

Effective vibration reduction:

BM Service LLC also provides services for the rental of overhead shock absorbers, which are designed to reduce vibrations that occur in the drill string during the drilling of a well. Our shock absorbers reduce the negative impact of vibrations on equipment and improve drilling efficiency.

We have shock absorbers of various diameters available to meet the requirements of different projects. Our team is ready to help you choose the most suitable shock absorber for your project, taking into account the specifics of the working conditions and performance requirements.

Flexibility and choice:

CORE SAMPLING EQUIPMENT

Our modern fleet

of core-collecting shells

of core-collecting shells

185/101,6 SDT-CTJ

3 sections with the possibility of selection for 1 flight up to 27m is an ideal choice for fast and high-quality core selection to great depths.

3 sections with the possibility of selection for 1 flight up to 27m is an ideal choice for fast and high-quality core selection to great depths.

172/101,6 HT-30

6 sections with the possibility of selection for 1 flight up to 54m - a reliable projectile capable of providing long-term work without loss of selection quality

6 sections with the possibility of selection for 1 flight up to 54m - a reliable projectile capable of providing long-term work without loss of selection quality

01

02

03

СК-171/80

3 sections with the possibility of sampling for 1 flight up to 18 m compact and maneuverable projectile for accurate core sampling in confined spaces

3 sections with the possibility of sampling for 1 flight up to 18 m compact and maneuverable projectile for accurate core sampling in confined spaces

185/101,6 SDT-CTJ

3 sections with the possibility of selection for 1 trip up to 18 m reliable tool with high productivity for efficient drilling and selection

3 sections with the possibility of selection for 1 trip up to 18 m reliable tool with high productivity for efficient drilling and selection

172/101,6 HT-30

6 sections with the possibility of selection for 1 flight up to 54m - a reliable projectile capable of providing long-term work without loss of selection quality

6 sections with the possibility of selection for 1 flight up to 54m - a reliable projectile capable of providing long-term work without loss of selection quality

04

05

the role of properselection and quality of chisels

The efficiency of drilling wells depends on the correct selection and quality of drill bits. Manufacturers are continuously improving the design of chisels using modern materials and technologies. Our company guarantees the supply of a high-quality and modern product that meets your requirements and needs.

Innovations and trends in the production of chisels

We are always following the current trends and innovations in the field of drill bit production. Together with our suppliers, we implement advanced developments and use modern technologies to provide you with the best equipment for successful well drilling.

Our

equipment

Downhole Motor

Drilling Jar

Chisels

Core sampling equipment

Slot filter

Check valves

Overflow valves

Centering elements

services